Gravity Roller Conveyors: Efficient, Cost-Effective Material Handling

Gravity roller conveyors provide a simple, motor-free way to move loads using only the force of gravity or manual push. Perfect for transporting items like cartons, packages, and pallets over short distances, they are widely used in warehouses, manufacturing plants, and shipping docks. Their design is cost-efficient and low-maintenance, requiring no electrical power, making them an ideal choice for businesses looking to optimize material handling without increasing operational costs. Easily scalable and adjustable, gravity roller conveyors can be customized to fit a variety of layouts and workflows.

Roller Conveyors: Versatile Solutions for Any Warehouse

Whether powered or gravity-driven, roller conveyors are indispensable tools for streamlining operations in warehouses and distribution centers. They are highly versatile, suited for everything from loading and unloading trucks at shipping docks to moving products along production lines or through order-picking areas. With their ability to handle various types of goods and adapt to different work environments, roller conveyors enhance efficiency, reduce manual labor, and ensure a smoother, faster workflow.

How to Choose the Right Gravity Roller Conveyor for Your Needs

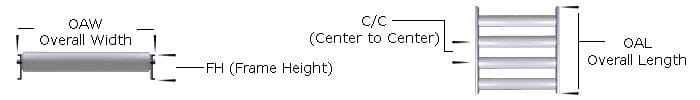

Selecting the right gravity roller conveyor depends on several key factors, including load capacity, roller diameter, frame material, and intended application. For light to medium loads, 1.5-inch diameter rollers are typically sufficient, while heavier loads require 1.9-inch or larger rollers with reinforced axles.

Frame materials such as galvanized steel or aluminum impact durability and suitability for different environments—galvanized steel is ideal for heavy-duty industrial settings, while aluminum is lightweight and resistant to corrosion. Additionally, roller spacing (centers) should match the size and shape of transported items to ensure smooth movement without sagging or instability.

Industries such as warehousing, manufacturing, distribution, and e-commerce fulfillment rely on gravity conveyors to streamline material handling, reduce labor, and improve workflow efficiency. To maintain peak performance, regular inspection, lubrication, and alignment are essential, preventing unnecessary wear and ensuring longevity. For assistance in choosing the best conveyor system for your specific needs, contact our expert team for personalized recommendations.