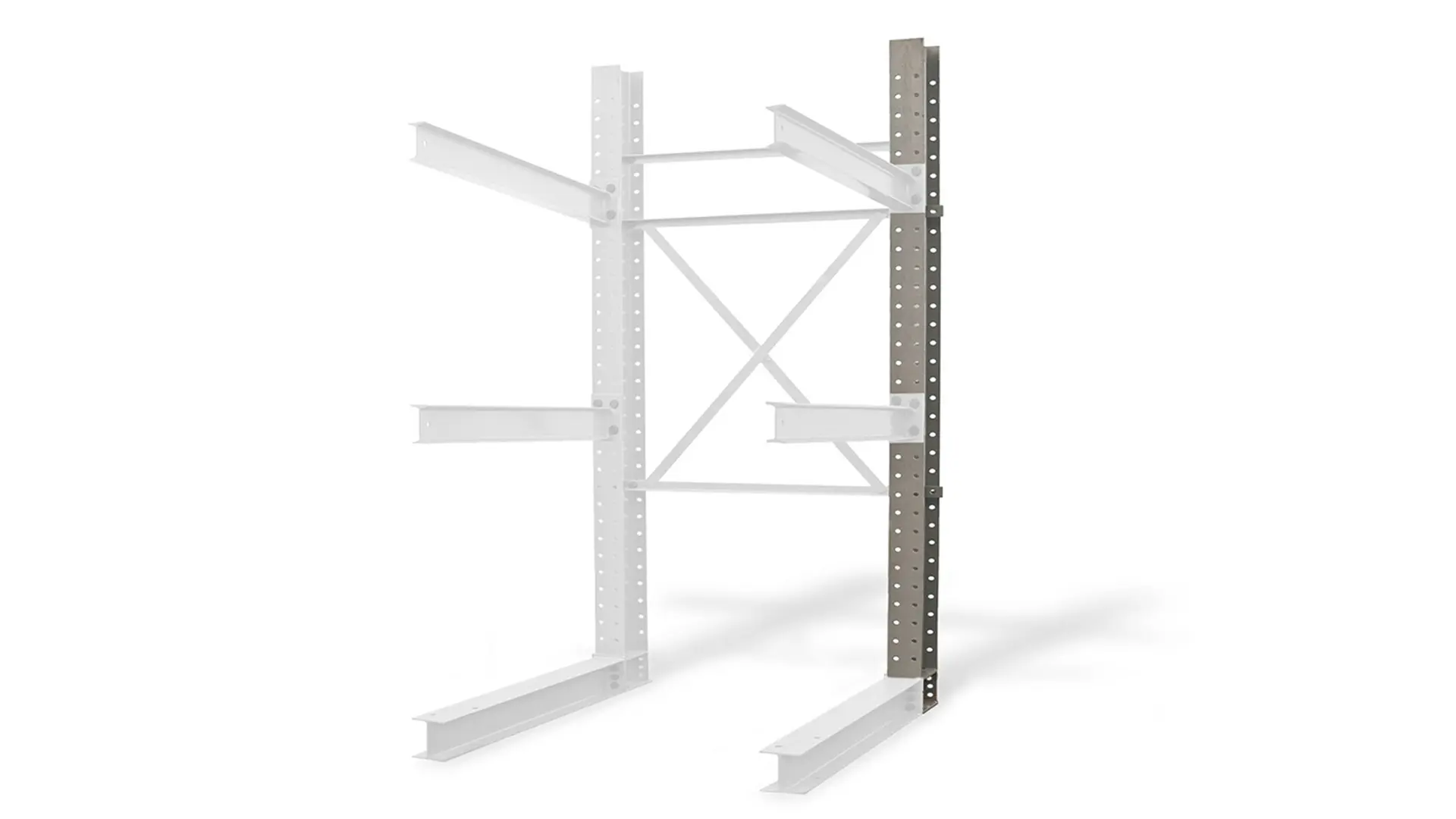

Cantilever racks are steel shelving units with long arms that extend from metal frames used to store long, bulky or awkward materials. They are used to store items such as furniture, lumber, PVC, metal pipes, steel bar stock, plywood, steel sheets, sheetrock and even cars.

Cantilever racks are configurable in countless different ways, allowing a flexible solution to fit any type of storage needs. They can be used both indoors and outdoors and are found in warehouses and storage yards across the world as an efficient storage solution.

In addition, cantilever racking can be decked to provide static storage similar to pallet racking, with the advantage that it provides easier storage and retrieval of bulky or oddly sized material than traditional pallet rack.

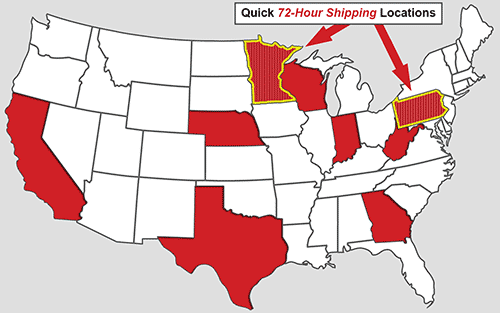

At SJF, you can find light duty, medium duty and heavy duty components, kits and cantilever systems in stock and ready to ship.

We can also help you find specialty cantilever systems such as cantilever lumber racks, auto racks and cantilever supported rack with roofs.

Cantilever racks are known by many names, such as:

- Cantilever racking system

- Cantilever storage racks

- Cantilever shelving

- Furniture cantilever rack

- Menards cantilever racks

- Cantilever pipe racking

- Lumber storage racks

- Cantilever lumber racks

- Cantilever steel racks

- Home Depot style racks

- Commercial lumber storage racks

- Lowes lumber racks

- and more

The storage density with cantilever racks can be very high if you plan out how you will use it efficiently, but generally cantilever rack's flexibility makes it a very popular storage solution with near immediate return on investment.