What is Drive In Racking and How is it Different from Other Pallet Rack Shelving Systems?

Buying Guide to High Density Pallet Rack Shelving Systems

If you have a lot of inventory that shifts on a regular basis, drive in or drive through rack is a high density pallet rack shelving solution you may want to consider.

While traditional static rack storage allows for many rows of pallet racking with aisles between individual rows, high density storage shelving allows for a much more dense, compact arrangement of your stored product.

Both drive in and drive through rack systems allow more efficient use of available space than traditional multi-aisle selective pallet racks systems because they are compacted into a tighter area. In fact, when compared to a conventional selective rack system, the same amount of storage can be achieved with a high density drive in or drive through pallet rack shelving system in 80% less space.

High density storage racks work by utilizing standard pallet rack uprights in conjunction with rail beams or more simply, rails to store the pallet loads in a very dense configuration.

Common Terms Often Associated With Drive In & Drive Through Racks

These are some terms associated with drive in pallet storage racking:

- Drive in racks

- Drive-thru racks

- Drive through racks

- Pallet flow racks

- Pallet flow rails

- Flow thru racks

- Push-back racks

- Spacesaver racks

- High density storage

- Deep pallet storage

- Mobile shelving

- Mobile storage shelving

Drive In Pallet Racks vs. Selective Pallet Racking

There are two key differences between drive in storage rack and selective pallet storage rack. With drive in rack, the forklift truck drives into the rack's bays to get to the stored product. With selective rack, the product is accessed from the front, back or sides of the rack but the forklift doesn't actually go inside the rack. There are no specified lanes between the rows with drive in. The bays can be as long or as short as needed.

Drive in rack and drive through rack systems decrease storage and retrieval time while increasing efficiency and productivity among workers. Not only do they benefit your operations, they can also decrease your bottom line by giving you more storage room per dollar spent on racking. Because these racks create a more uniform load in a confined storage area, your forklift operators working in the system become more skillful drivers. In addition to these benefits, consider this – drive in and drive through systems are very energy efficient. Since the product is so densely loaded in this type of system, there is less air to be heated or cooled between your pallets and your forklifts don't need to drive as far to pick or place loads, thereby using less fuel.

Pallet Racking vs. Drive In Racking Comparison

Clearly, drive in or drive through is not for every warehouse, however it is exceptionally good at storing large quantities of palletized materials in a smaller space than would be afforded by selective pallet rack (see figure 6).

Within the class of drive in or drive through racks are several notable configurations – most commonly defined by the length of storage time and ease of retrieval needed for the product being stored (see figure 7).

One Way Drive In – Last In First Out (LIFO)

Material is both stored and retrieved from the same side (entry point) in several aisles. For this reason, the first material put in this system is the last to come out. This works well where shelf life is at a minimum or not a major concern. This system also works well in cold storage environments or warehouse freezers.

Two Way Drive In – Multi First In Last Out System

Arranging drive in to be enter-able from two sides allows for maximum space usage and easy product accessibility from two separate sides.

Drive Through – First In First Out (FIFO)

Free access from both sides allows materials to be stored from one end and retrieved from the other. With this capability, a first in/first out storage arrangement is made possible. This system is used where there is expiration-dated material or wherever shelf life is of major concern.

Push-Back Rack

A Push-Back Racking System can be a great option for warehouses tight on space. In a push-back rack system, each pallet sits on a tray that rides along rails in the rack frame itself. The push-back rails are supported on an incline and gravity moves the trays along the rails toward the front of the rack. From the front, the loads are both picked and deposited while the back of the rack remains closed. When a load is deposited to the front of the rack, it will "push back" the previously placed load, thus decreasing picking times but keeping the number of picking faces to choose from high.

Push-back racks can store multiple sized pallets up to six deep and four high, making push-back rack a very efficient LIFO (last-in, first-out) system. This type of dynamic storage system allows you to have all the benefits of a high-density storage system without the drawbacks of a drive-in system. Let's look at this further.

With a typical high-density drive in system, each bay will typically be filled with the same type of product. That way, when retrieving products, one needs only to go to that 'pick-face' to get any one item. If dissimilar items were to be placed in the same bay, that entire bay may potentially need to be unloaded to get at the needed product, thus wasting a large amount of time and resources.

However, with a push-back system, many different products can be placed in lanes within the same bay allowing for a larger quantity of pick faces. With each individual lane being a separate product, those products will still be accessible without first unloading the rack.

Pallet Flow Storage Racks

Similar in concept to push-back rack is a Pallet Flow System. The pallets move from back-to-front and as they are removed from the rack, the next in line takes the previous pallet's place. Unlike push-back rack however, the rack is usually loaded from the back and picked from the front.

Almost any static pallet rack system can be retrofitted to be a more efficient dynamic storage system because the pallet flow rails drop into place using the existing racking components as their support structure. Lanes of pallet flow rails usually have built-in 'brakes' that work to slow the pallets to a smooth gentle pace as they glide down the lane. One of the biggest strengths of pallet flow rails over push-back is that flow rails will allow a longer lane. For example, while push-back may be able to store pallets five deep, a pallet flow system will allow as many as 10-15 pallets deep.

Looking for "Pallet Rack Near Me?"

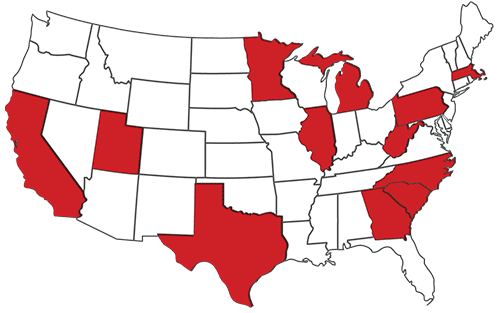

Pallet Racking Systems Shipping Locations - We Ship NATIONWIDE

SJF Material Handling Inc. ships warehouse racking systems from multiple locations:

- California

- Georgia

- Illinois

- Massachusetts

- Michigan

- Minnesota

- North Carolina

- Pennsylvania

- South Carolina

- Texas

- Utah

- West Virginia

- Ontario, Canada