What is Drive In Rack & Drive Through Rack?

Guide to Drive In Rack / Drive Through Rack... The Basics

Both drive in and drive through racking systems allow more efficient use of available space than traditional multi-aisle selective rack. In fact, when compared to a conventional selective racking system, the same amount of storage can be achieved with a high density system in 80% less space. These systems decrease storage and retrieval time while increasing efficiency and productivity among workers. Not only do they benefit your operations, they can also decrease your bottom line... Which gives you more storage room per dollar spent on racking.

The ways these systems achieve such high efficiency are deceptively easy:

(a) They create a more uniform load, and

(b) They create loads in a confined storage area, all while

(c) Forklift operators working in the system become more skillful drivers.

In addition to the above benefits, one more thing can be said about this type of system: Energy efficiency. Since the product is so densely loaded in this type of system, there is less air around it to be heated or cooled.

Drive In Racking

Drive In Racking is the ultimate in high-density storage. No other form provides more storage capacity per square foot of room than drive in. A viable alternative to expanding one's facility, drive in rack provides a very low cost yet efficient means of high volume storage.

One Way Drive In - Last In First Out (LIFO) -

Material is both stored and retrieved from the same side (entry point) in several aisles. For this reason, the first material put in this system is the last to come out. This works well where shelf life is at a minimum or not a major concern. This system also works well in cold storage environments or warehouse freezers.

Two-Way Drive In - Multi First In Last Out System - Arranging drive in rack to be enter-able from two sides allows for maximum space usage and easy product accessibility from two separate sides.

Drive Through Racking

Drive Through Racking is similar to drive in rack, although a drive through system allows access to stored materials from two sides.

Drive-Through - First In First Out (FIFO) -

Free access from both sides allows materials to be stored from one end and retrieved from the other. With this capability, a first in first out storage arrangement is made possible. This system is used where there is expiration dated material or wherever shelf life is of major concern.

Looking for "Pallet Rack Near Me?"

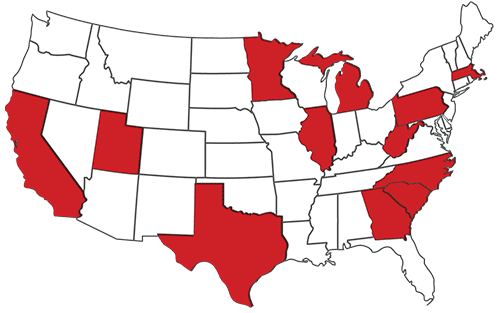

Pallet Racking Systems Shipping Locations - We Ship NATIONWIDE

SJF Material Handling Inc. ships warehouse racking systems from multiple locations:

- California

- Georgia

- Illinois

- Massachusetts

- Michigan

- Minnesota

- North Carolina

- Pennsylvania

- South Carolina

- Texas

- Utah

- West Virginia

- Ontario, Canada