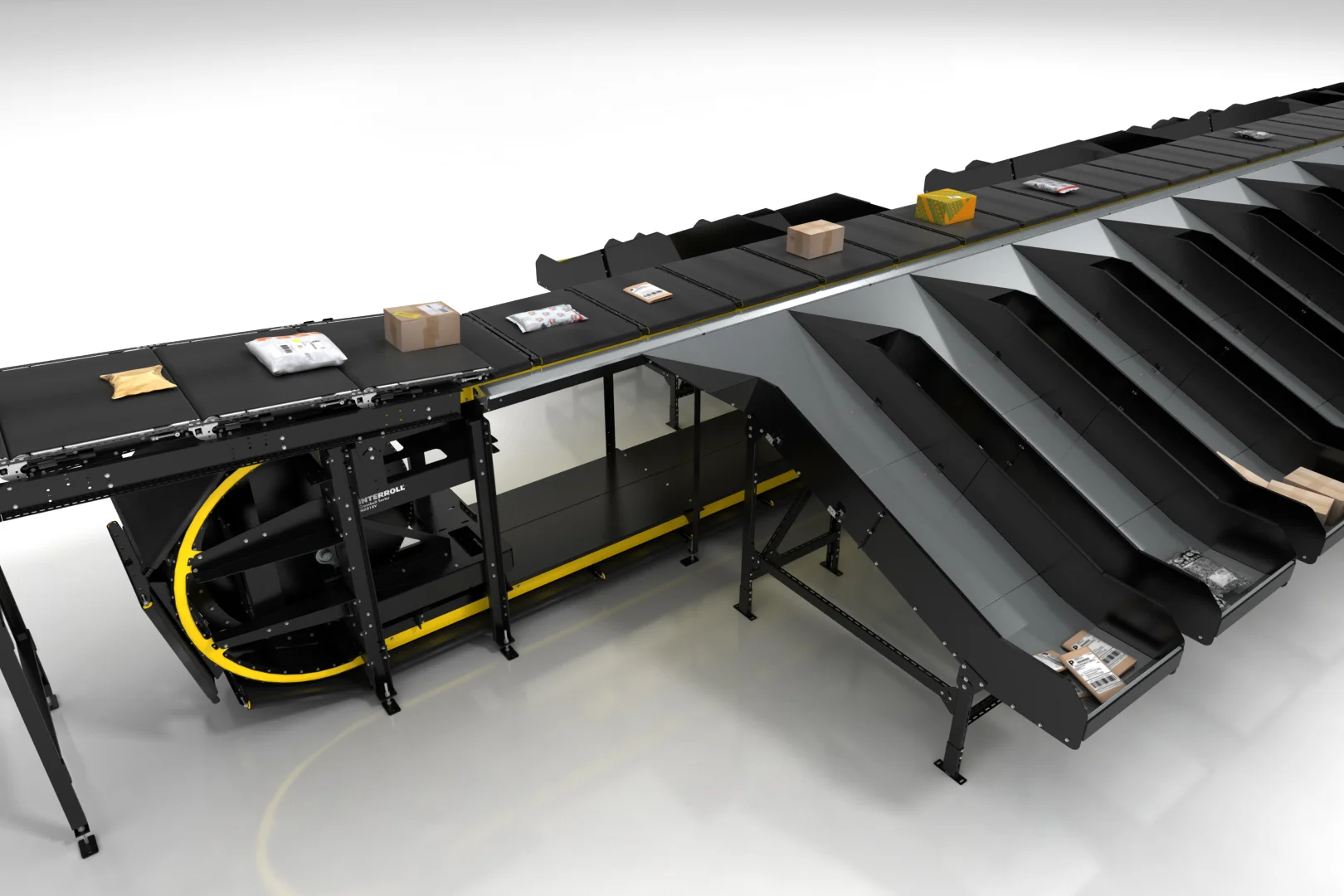

Vertical Cross Belt Overview

A Vertical Crossbelt Sorter is an advanced material handling system used for efficient and accurate sorting of items in distribution and order fulfillment centers. This automated sorting solution features a network of carriers equipped with crossbelts that move vertically and horizontally across multiple levels. As items travel on these crossbelts, they are diverted to designated chutes or bins based on predefined criteria such as destination, order, or SKU. Vertical Crossbelt Sorters are known for their high throughput, flexibility, and suitability for a wide range of products, making them integral to modern logistics operations.

Rate:

Approximately 12,500 units/hr