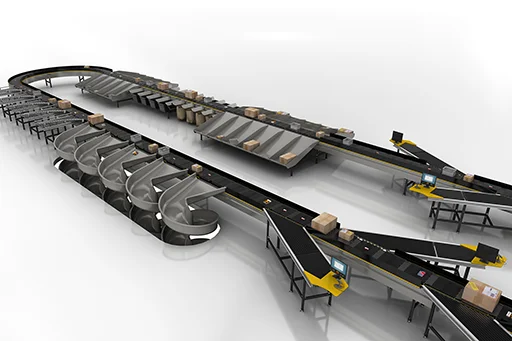

Sortation Overview

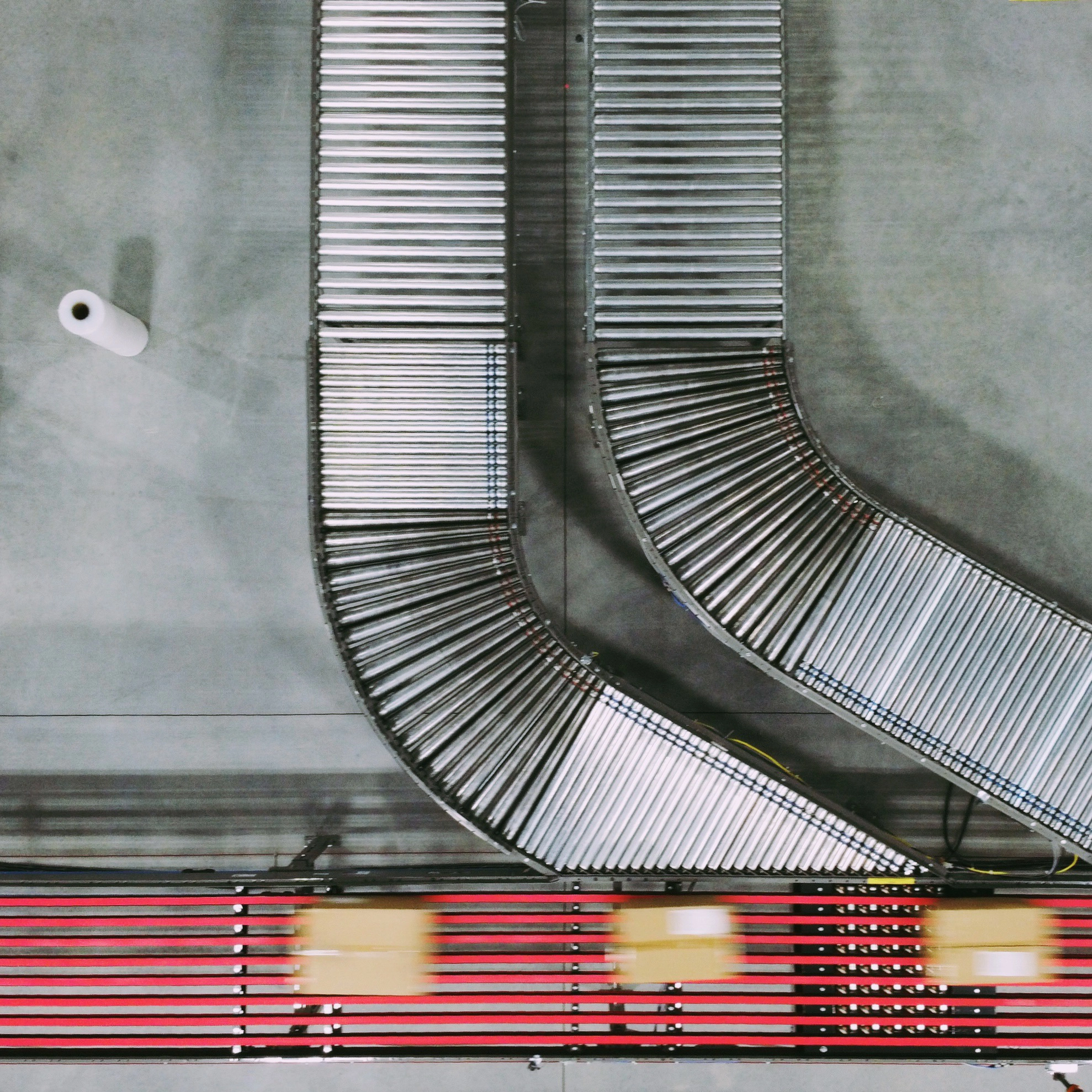

Sortation conveyors are specialized conveyor systems designed to automate the process of sorting or routing items or packages within a facility, such as a warehouse, distribution center, or e-commerce fullfillment center. While conveyors are used to facilitate the movement of products between two points, sortation systems are used to direct product to specific endpoints.

Adding sortation capability to your conveyance system increases productivity and efficiency by mechanically routing products to different destinations, or to separate product based on a set of sort criteria. This criteria can include destinations, customer orders, ship method, pack method, or SKU. Sortation mechanisms, called diverters, are combined with sensors and WCS (Warehoue Control System) integration to accurately and efficiently perform these functions without adding additional labor to the process.

There are a variety of different sorters to handle product from cases, totes, and polybags, as well as individual units such as books, tires, pallets, etc. SJF Solution Specialists can help you determine what solution will work best for your application. From lower speed and less complex to high speed fully integrated systems, selecting the right solution is critical for operational success.