In the world of warehouse management, pallet racking plays a pivotal role. It’s the backbone of industrial storage, optimizing space and efficiency.

But with a myriad of options available, how do you choose the right one? This guide aims to simplify that decision. We are also always available to answer questions or to help you decide what’s right for you. Contact a SJF Solutions Specialist at (320) 485-4974 or email support@sjf.com, or fill out our simple online form. Our advice is always free.

We’ll delve into the different types of pallet racking systems, from selective to teardrop, and drive-in to cantilever. Each type has its unique benefits and considerations.

We’ll also explore factors to consider when selecting a system. These include load capacity, warehouse layout, and inventory accessibility.

Finally, we’ll touch on the future of pallet racking in warehouse storage. As technology evolves, so do the possibilities for more efficient and effective storage solutions.

So, whether you’re a warehouse manager, a logistics professional, or a business owner, this guide is for you. Let’s dive in and explore the world of pallet racking options.

Understanding Pallet Racking and Its Importance

Pallet racking is a storage system designed to hold materials on pallets or skids. It’s a crucial component of warehouse storage, enabling businesses to store more in less space.

The importance of pallet racking extends beyond space optimization. It also enhances efficiency, allowing for quicker access to stored items. This can significantly improve inventory management and order fulfillment processes.

Types of Pallet Racking Systems

There are several types of pallet racking systems, each with its unique features and benefits. The choice of system depends on the specific needs of a warehouse, including the type of goods stored, space availability, and inventory management requirements.

Selective Pallet Racking

Selective pallet racking is the most common type of racking system. It allows for the direct access to all pallets, making it a versatile choice for a wide range of industries.

This system is ideal for warehouses with a high variety of SKUs and lower volumes of each. It’s also suitable for both FIFO (First In, First Out) and LIFO (Last In, First Out) inventory management.

Teardrop Pallet Racking

Teardrop pallet racking is named for the teardrop-shaped holes on the upright frames. This design allows for easy assembly and reconfiguration, making it a flexible option for dynamic warehouse environments.

The system is compatible with various brands, offering a cost-effective solution for businesses looking to expand or modify their existing racking.

Drive-In and Drive-Through Racking

Drive-in and drive-through racking systems are designed for high-density storage. They allow forklifts to drive directly into the racking, enabling more efficient use of space.

Drive-in racking is ideal for LIFO inventory management, while drive-through racking supports FIFO management. These systems are best suited for warehouses with large quantities of similar products.

Push-Back Racking Systems

Push-back racking systems allow pallets to be stored in depth, increasing storage density. When a new pallet is added, the existing ones are pushed back.

This system is a form of high-density storage that allows for both selectivity and efficient use of space. It’s ideal for LIFO inventory management.

Pallet Flow Racking

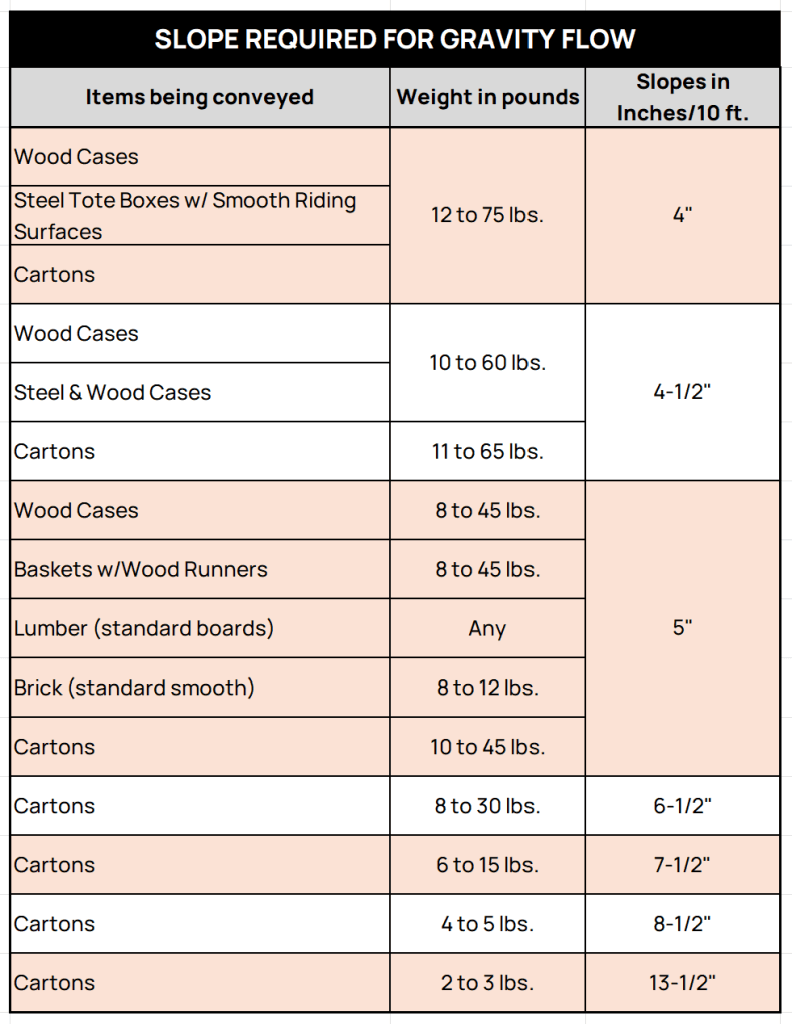

Pallet flow racking, also known as gravity flow racking, uses a first-in, first-out storage system. Pallets are loaded onto one end of the rack and move towards the other end due to gravity.

This system is ideal for high-volume, high-turnover businesses that require efficient stock rotation. It’s particularly useful for perishable goods that need to be moved out quickly.

Cantilever Racking

Cantilever racking is designed for long or bulky items that don’t fit on regular pallets. The system features arms extending from a single column, allowing for easy loading and unloading.

This type of racking is commonly used in industries dealing with timber, pipes, or other long materials. It offers a flexible storage solution that can be adjusted to accommodate different load lengths.

Factors to Consider When Selecting Pallet Racking

Choosing the right pallet racking system is crucial for efficient warehouse operations. Several factors come into play when making this decision. These include load capacity, warehouse layout, and inventory management needs.

Load Capacity and Material Handling

The load capacity of a racking system is a key factor to consider. It’s important to choose a system that can safely support the weight of your goods. The type of material handling equipment used also influences the choice of racking. For instance, some systems are designed to accommodate forklift access.

Warehouse Layout and Space Utilization

The layout and available space in your warehouse significantly impact the type of racking system you can install. Some systems, like VNA (Very Narrow Aisle) and drive-in racking, are ideal for warehouses with limited space. Others, like selective racking, require more aisle space for easy access to pallets.

Inventory Accessibility and Management

Your inventory management strategy also influences the choice of racking. For instance, if you operate on a FIFO basis, a pallet flow racking system would be suitable. On the other hand, if you use a LIFO system, push-back or drive-in racking might be a better choice.

Pallet Racking Accessories and Customization

Pallet racking systems can be enhanced with various accessories to improve functionality and safety. These accessories can also help customize the system to better suit your specific needs.

Some common pallet racking accessories include:

Safety and Compliance in Pallet Racking

Safety is a paramount concern in any warehouse setting. Pallet racking systems should be designed and installed with safety in mind, adhering to industry standards and regulations.

Regular inspections and safety audits are crucial to ensure the integrity of the racking system. Training staff on safe racking practices can also help prevent accidents and maintain a safe working environment.

The Future of Pallet Racking in Warehouse Storage

The future of pallet racking is likely to be influenced by advancements in technology. Automated storage and retrieval systems (AS/RS) and software for managing pallet racking systems are already making an impact.

Sustainability is another key trend, with more businesses considering the environmental impact of their racking materials and seeking out sustainable solutions.

Conclusion: Optimizing Your Warehouse with the Right Pallet Racking

Choosing the right pallet racking system is crucial for optimizing your warehouse. It can enhance storage capacity, improve inventory management, and boost operational efficiency. Always consider your specific needs, safety standards, and future growth plans when selecting a pallet racking solution.